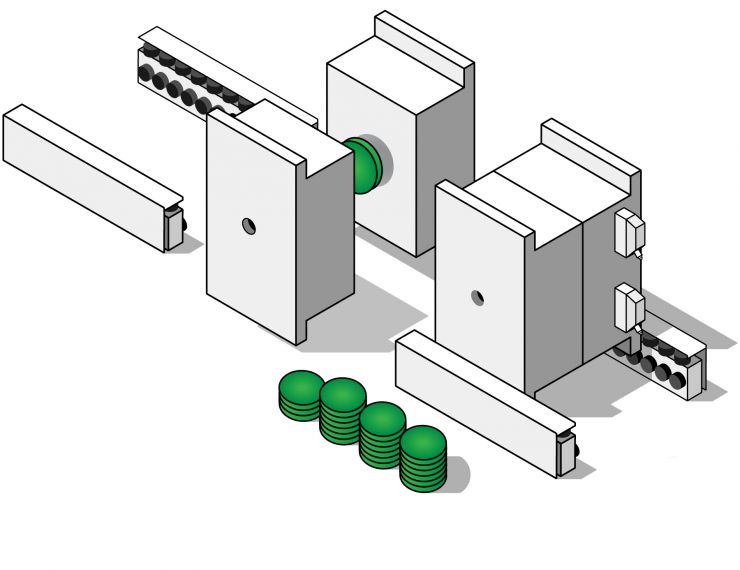

Scientific molding can optimize the entire molding process except cooling time. Multi Mold System converts wasteful cooling time into production time by shuttling the two different molds in and out of the injection molding machine

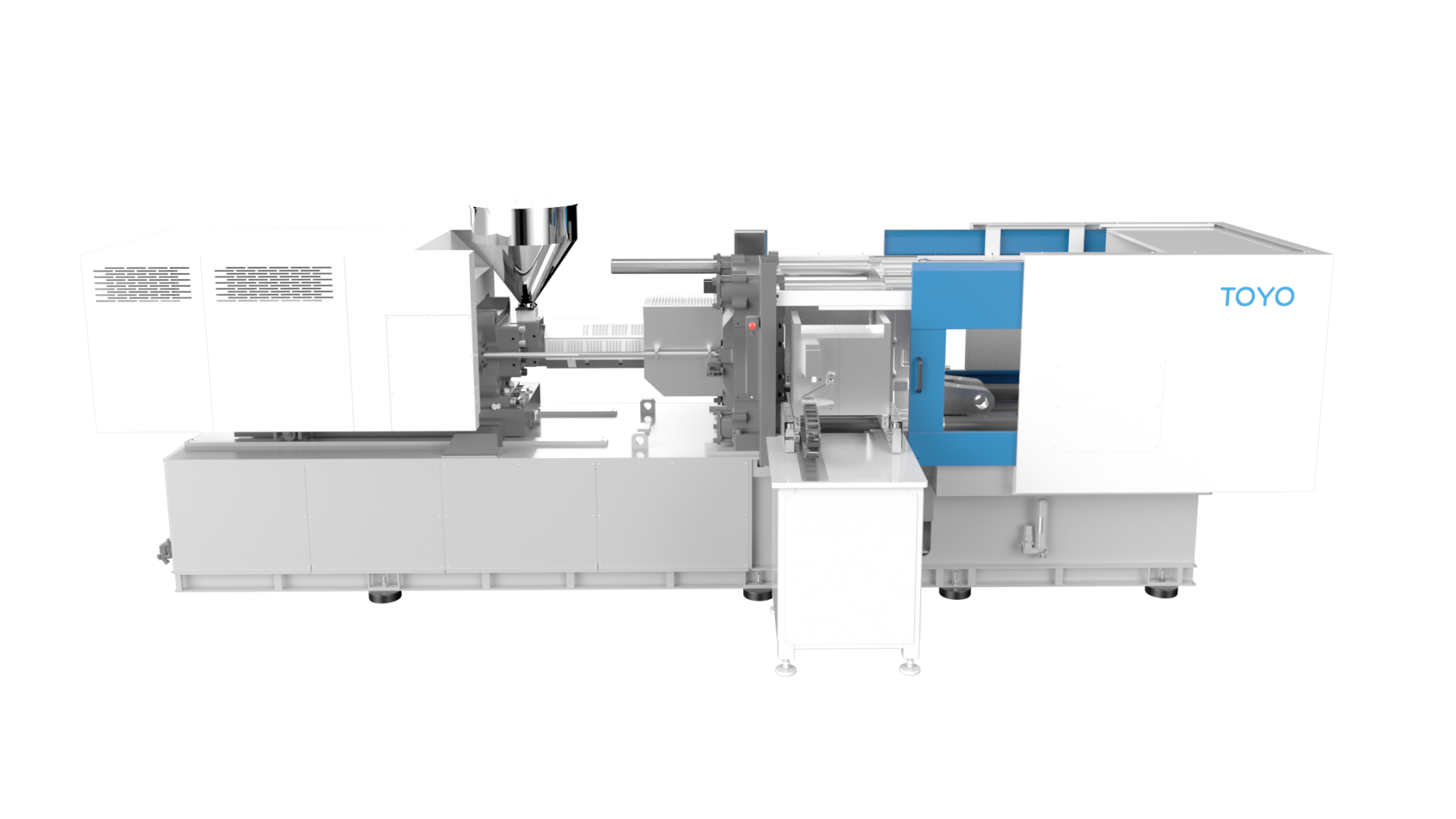

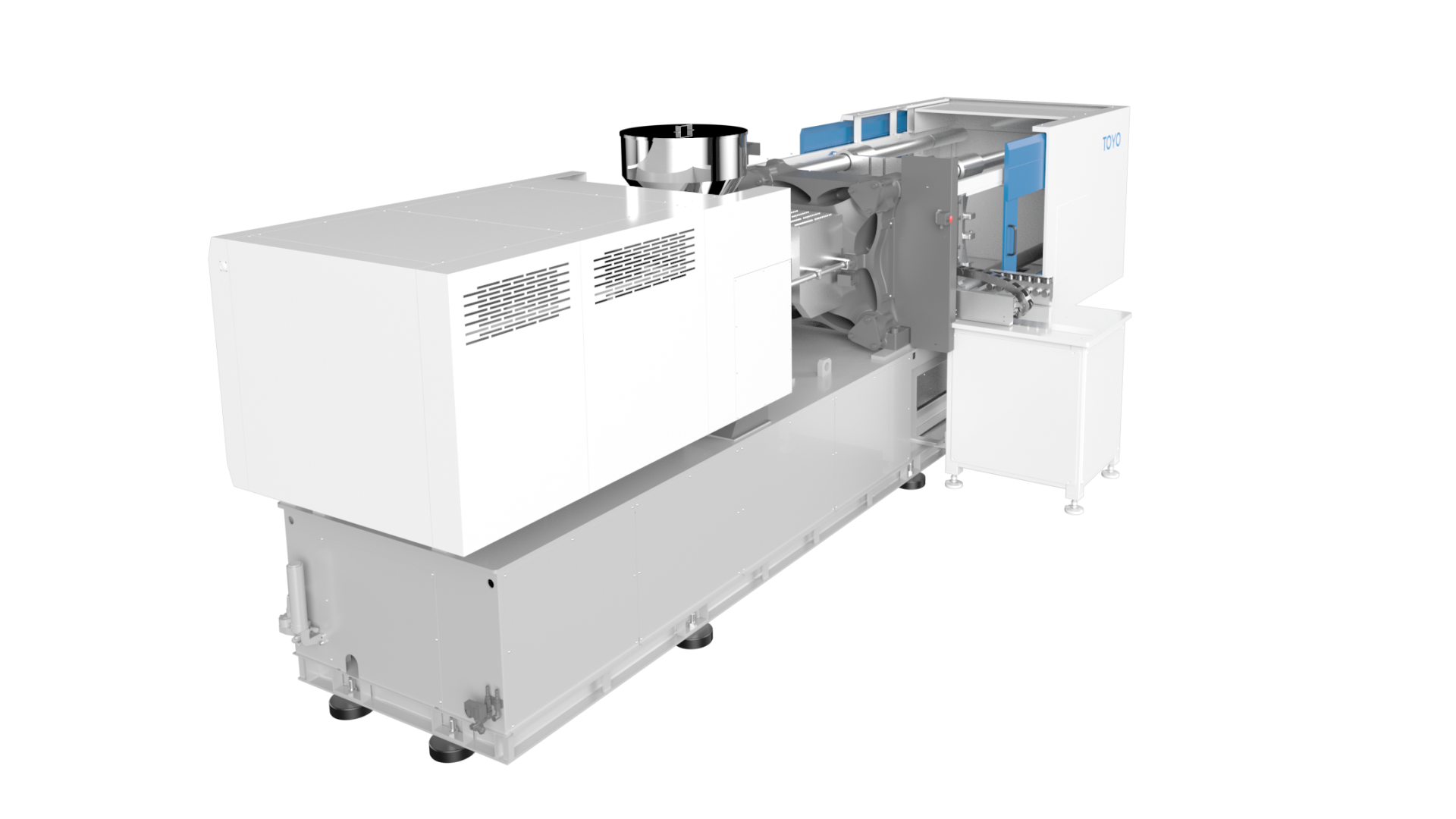

MULTI MOLD

SYSTEM

• Utilizing the wasteful cooling time,

Multi Mold System increases capacity

up to double by alternately running

two different molds on a single

molding machine

• Developed by Canon, Multi Mold

has been used in Canon

production facility for Inkjet

Printer parts since 2014

UP TO 2X CAPACITY

Production FlexibiliTY

Features and benefits

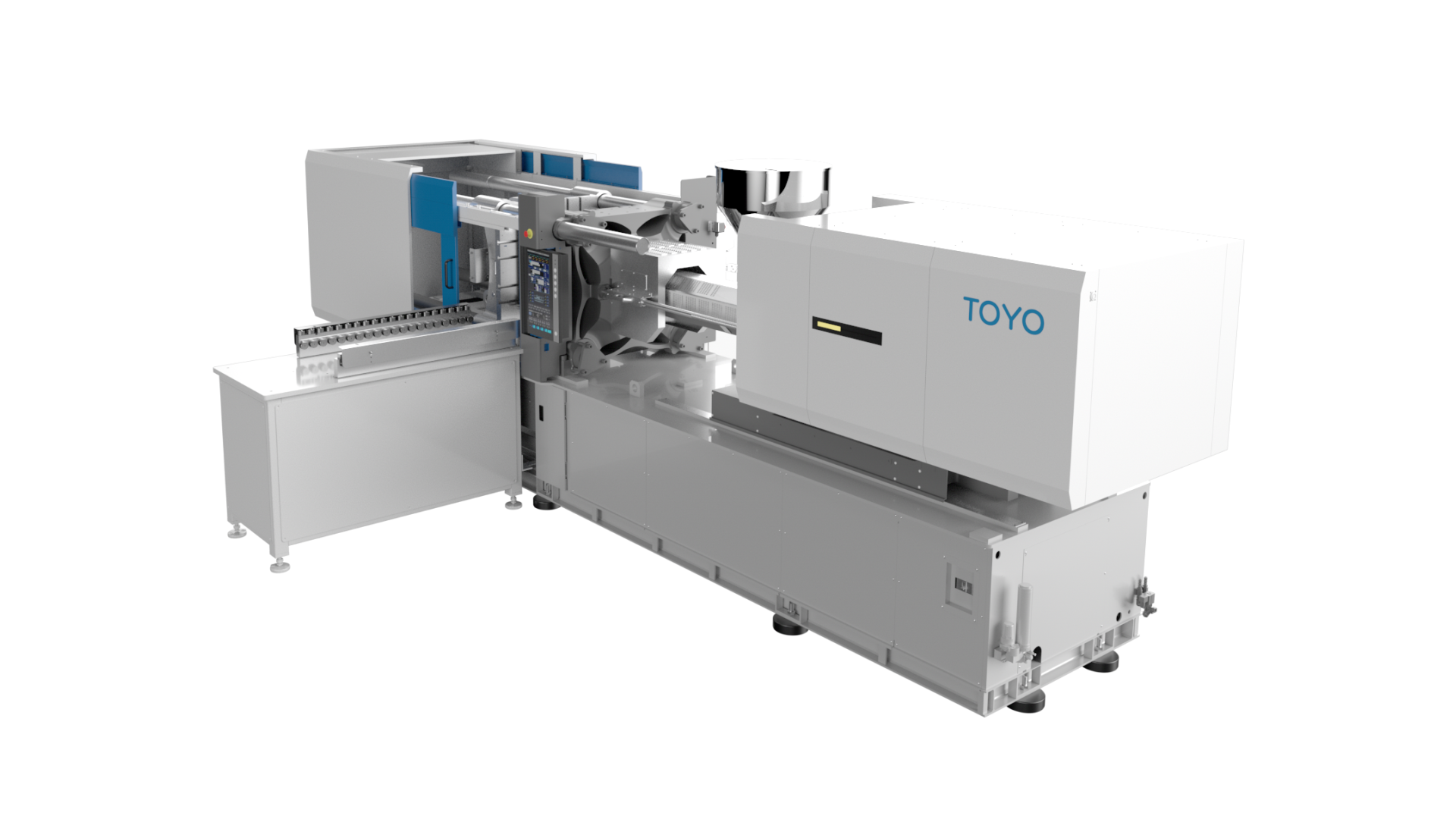

OPTIMIZE CAPACITY

AUTONOMOUS CONTROL

Multi Mold System is able to automatically control different molding condition for each die

ZERO DOWNTIME

Only takes seconds for changeover completely eliminating downtime

WIP MANAGEMENT

Reduces parts inventory space realizing the JUST-IN-TIME assembly in your operation

FAQ

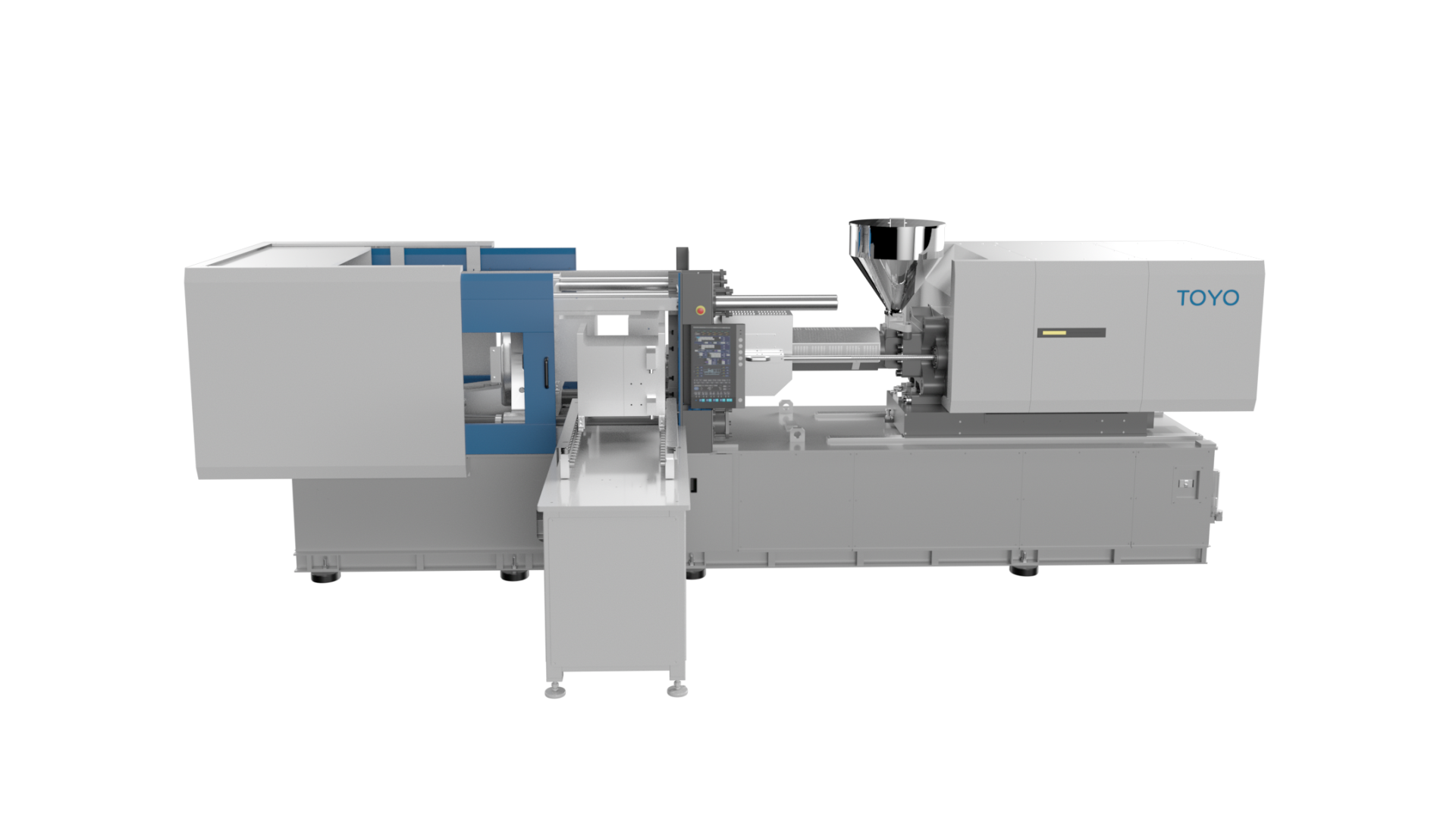

DO WATER LINES STAY CONNECTED TO THE DIES?

Yes. You can use the existing dies with some modifications.

AFTER INSTALLING THE MULTI MOLD SYSTEM, CAN I RUN THE MACHINE LIKE A NORMAL MACHINE?

Yes. You can turn “off” the shuttling function and runs it like a normal injection machine.

CAN I USE THE MULTI MOLD SYSTEM WITH THE EXISTING MACHINE?

Yes, with some modifications

WHAT IS THE MAXIMUM DIE WEIGHT?

It varies by the model of Multi Mold System. Please contact the sales team.